Comprehensive Guide to Jumbo Bags (FIBC)

Comprehensive Guide to Jumbo Bags (FIBC)

Jumbo Bags, also known as FIBC (Flexible Intermediate Bulk Containers), are large industrial containers made of woven polypropylene fabric, designed for storing and transporting dry, flowable products such as sand, fertilizer, cement, chemicals, and granules.

1. Structure and Material

A standard Jumbo Bag is made from woven polypropylene (PP) fabric. The fabric can be coated or uncoated depending on the product type and required protection from moisture or contamination.

It usually includes lifting loops, a filling spout, a discharge spout, and sometimes an inner liner for extra protection.

2. Types of Jumbo Bags

Jumbo Bags come in several types based on their construction and application:

- Type A: Standard non-conductive bags used for non-flammable materials.

- Type B: Similar to Type A but with low breakdown voltage to prevent brush discharges.

- Type C: Conductive bags made with carbon or conductive threads, requiring grounding during use.

- Type D: Anti-static bags that dissipate static charge safely without grounding.

3. Standard Sizes and Capacities

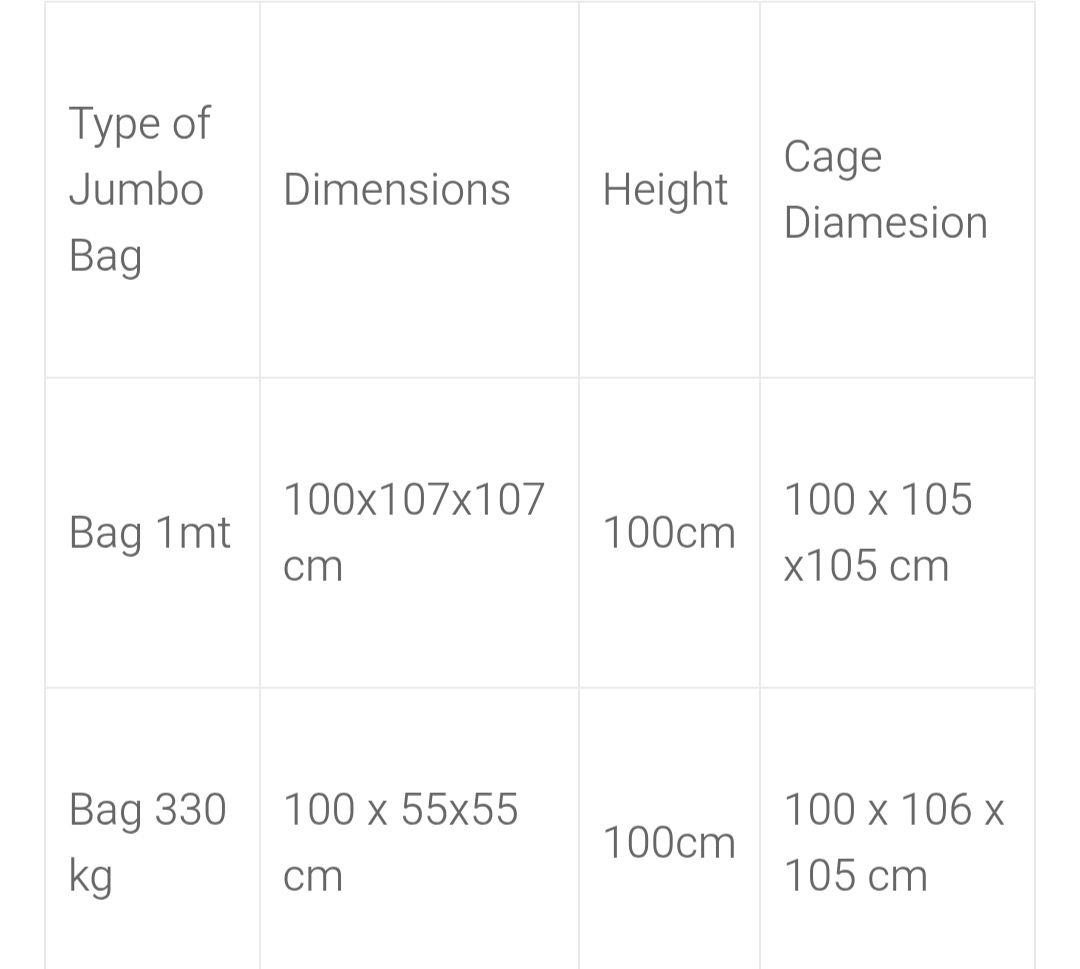

Jumbo Bags typically range from 500 kg to 2000 kg capacity. The most common dimensions are between 90x90x110 cm and 100x100x150 cm, with volume capacities from 0.5 to 2.0 cubic meters.

4. Applications

Jumbo Bags are widely used across industries including:

- Cement and construction materials

- Mining and minerals

- Chemicals and petrochemicals

- Agriculture and fertilizers

- Food and pharmaceuticals (in food-grade FIBCs)

5. Advantages

- High durability and load capacity

- Reusable and recyclable

- Cost-efficient for bulk transportation

- Easy to handle with forklifts or cranes

- Space-saving and flexible storage

6. Quality and Safety Standards

High-quality FIBC bags are manufactured under ISO 21898 standards and often certified for UN hazardous materials transport. Testing includes top lift, drop, tear, and UV resistance.

7. Sustainability and Recycling

Polypropylene Jumbo Bags are recyclable and can be reprocessed into new industrial products. Many manufacturers now focus on eco-friendly coatings and reuse cycles to reduce plastic waste.

8. About Jumboo Bag Company

Jumboo Bag is a professional manufacturer and supplier of high-quality FIBC Jumbo Bags.

Our products are designed for heavy-duty applications in petrochemical, mining, cement, and agricultural industries.

We are committed to delivering durable, safe, and cost-effective packaging solutions that meet global standards.

Fabrics Used in Jumbo Bags (FIBC Fabric Overview)

The fabric used in Jumbo Bags, also known as FIBC (Flexible Intermediate Bulk Container) fabric, is a high-strength woven polypropylene (PP) material specially designed to carry and protect bulk materials.

It provides durability, flexibility, and resistance to tearing, moisture, and UV exposure — essential for industrial packaging and transport.

1. Material Composition

The primary material is polypropylene (PP), a thermoplastic polymer known for its strength and lightweight properties. Depending on the application, the fabric may be:

•Uncoated (plain woven) – allows air circulation and is used for products like grains or minerals.

•Coated (laminated) – covered with a thin PP film layer to make it moisture-resistant for products like cement or fine powders.

2. Fabric Construction

•Warp and Weft: The PP tapes are woven together on circular or flat weaving looms to create a strong mesh structure.

•Denier / GSM: The yarn thickness and fabric weight (measured in GSM—grams per square meter) determine the bag’s strength and load capacity.

Typical fabric weight ranges from 130 GSM to 220 GSM.

•UV Stabilization: Additives are mixed with PP granules to protect the fabric from sun degradation during outdoor storage.

3. Types of Fabric

•Standard PP Fabric: For general-purpose jumbo bags.

•Conductive Fabric (Type C): Contains carbon threads to safely dissipate static electricity.

•Anti-static Fabric (Type D): Prevents static build-up without grounding.

•Food-grade Fabric: Made from virgin PP resin under hygienic conditions.

4. Fabric Testing and Quality Control

Each roll of FIBC fabric is tested for:

•Tensile strength

•Tear resistance

•UV stability

•Coating adhesion

•Air permeability

These tests ensure the bags can safely handle loads from 500 kg to 2000 kg without deformation or rupture.

5. Environmental and Recycling Aspects

PP woven fabric is 100% recyclable. Many manufacturers collect used bags and reprocess them into secondary plastic products. Eco-friendly coatings and biodegradable options are being developed to reduce environmental impact.

⸻

📍 In short:

The quality of the fabric determines the strength, safety, and performance of a Jumbo Bag.

High-grade PP woven fabric ensures reliable bulk packaging for industries such as cement, chemicals, fertilizers, and minerals.

Jumboo Tarkhan – Exporting High-Quality Jumbo Bags Worldwide

Jumboo Tarkhan is a leading Iranian manufacturer and exporter of FIBC Jumbo Bags (Flexible Intermediate Bulk Containers), offering reliable bulk packaging solutions to industries across the globe.

With years of experience in the production of polypropylene (PP) woven jumbo bags, the company has established a strong reputation for quality, innovation, and customer satisfaction.

1. Global Export Presence

Jumboo Tarkhan exports its products to several international markets in Asia, the Middle East, Africa, and Europe.

Our jumbo bags are trusted by clients in industries such as:

•Petrochemical and chemical industries

•Mining and mineral processing

•Cement and construction materials

•Agriculture and fertilizers

•Food and pharmaceutical packaging

Each product complies with international packaging and safety standards (ISO 21898, UN Certified) to ensure reliability during international transport and handling.

2. Export-Grade Quality and Customization

We produce custom-designed Jumbo Bags based on client specifications:

•Size: 500 kg to 2000 kg capacity

•Type: Type A, B, C, and D FIBC bags

•Liner options: PE inner liners, anti-static, and conductive liners

•Printing and branding according to customer requirements

Our export team ensures each order undergoes strict quality checks — from fabric weaving to final inspection — to guarantee perfect performance in diverse environmental conditions.

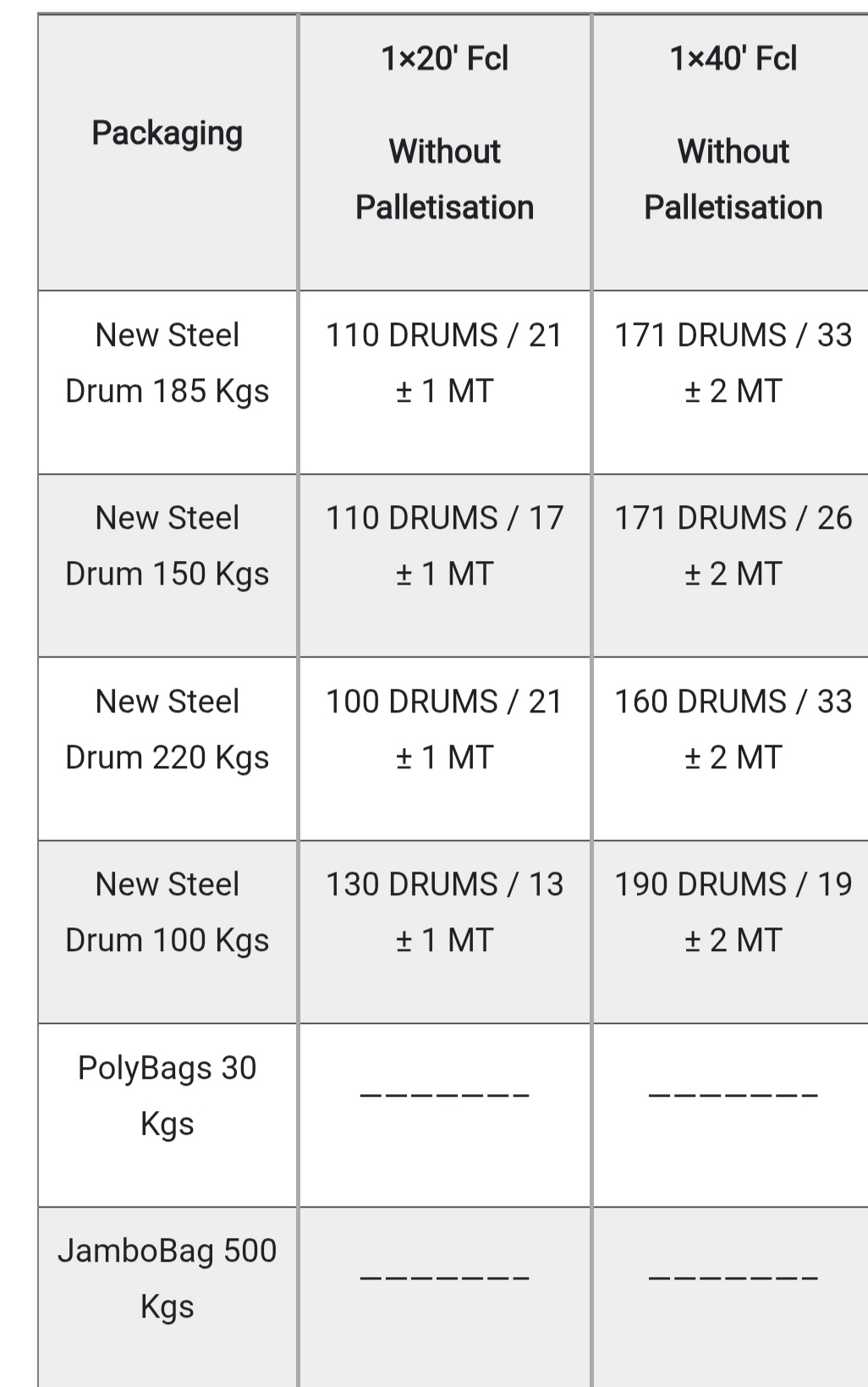

3. Logistics and Packaging Solutions

Jumboo Tarkhan provides efficient export logistics services including:

•Sea and land shipping coordination

•Palletized and compressed packaging for container optimization

•Export documentation and certificates of origin

We aim to deliver not only premium packaging products but also seamless international service.

4. Sustainability Commitment

Our production is designed to minimize environmental impact.

We use recyclable PP materials and continuously improve our manufacturing processes to support sustainable export operations.

5. Why Choose Jumboo Tarkhan for Export

•Experienced FIBC manufacturer with global export capability

•ISO and UN-certified jumbo bags

•Competitive pricing and consistent quality

•On-time international delivery

•Dedicated export support team

⸻

🌍 Jumboo Tarkhan – Exporting Strength, Safety, and Sustainability

For export inquiries:

📧 info@jambootarkhan.ir

🌐 www.jambootarkhan.ir

For inquiries or product catalogs, please contact:

#JumboBags

#FIBCBags

#BulkPackaging

#IndustrialPackaging

#FlexibleBulkContainers

#BigBags

#BulkBags

#JumbooBag

#FIBCSupplier

#FIBCManufacture

#CementPackaging

#ChemicalPackaging

#MiningIndustry

#PetrochemicalPackaging

#AgriculturePackaging

#FoodGradeFIBC

#PPWovenBags

#PolypropylenePackaging

#BulkMaterialHandling

#ConstructionMaterials

⸻

🔹 فنی و کیفیت

#HeavyDutyPackaging

#DurableBags

#EcoFriendlyPackaging

#RecyclablePackaging

#UNCertifiedFIBC

#AntistaticBags

#ConductiveFIBC

#SafetyPackaging

#QualityControl

#ISOStandard

⸻

efibc.com

Bulk Bag Depot

ایالات متحده آمریکا

یکی از بزرگترین تأمینکنندگان FIBC در آمریکا، دارای موجودی بالا و خدمات سریع.

bulkbagdepot.com

DIV Trades

صربستان

تولیدکننده بزرگ “big bags / FIBC” در اروپا با ظرفیت حدود 1٫5 میلیون کیسه در سال.

divtrades.com

JUTA a.s.

جمهوری چک

با بیش از سی سال تجربه تولید FIBC و «یکی از تولیدکنندگان پیشرو در اتحادیه اروپا».

juta-big-bags.com

isbir Bulk Bag USA

ترکیه / آمریکا

ظرفیت بسیار بالا؛ در توضیح آمده که «capacity of 15 millions Bulk Bag, FIBC».

isbirusa.com

#ExportQuality

#GlobalPackagingSolutions

#IndustrialSupply

#PackagingInnovation

#MadeInIran

#PackagingManufacturer

Website: www.jambootarkhan.ir

Email: info@jambootarkhan.ir

Jumbo Bag Packaging in Bitumen Industry

In the bitumen industry, choosing the right packaging method is crucial for ensuring product safety, maintaining quality, and optimizing logistics. One of the most commonly used and cost-effective packaging solutions in bitumen distribution is Jumbo bag packaging. In this article, we will explore the advantages of Jumbo bag packaging in bitumen, compare it with other common packaging types, and highlight why it is becoming the preferred choice for many manufacturers and suppliers in the industry.

What is Jumbo Bag Packaging in Bitumen?

Jumbo bag packaging in bitumen refers to the use of large, flexible, and durable bags designed to hold and transport bitumen. These bags are typically made of woven polypropylene material, which can handle large volumes of bitumen while offering protection from environmental factors such as moisture and contamination. Jumbo bags are also known as FIBCs (Flexible Intermediate Bulk Containers), and they can hold anywhere between 500 kg to 2,000 kg of bitumen, depending on the specifications required by the supplier or customer.

Advantages of Jumbo Bag Packaging in Bitumen

Jumbo bag packaging in bitumen offers several key advantages over alternative packaging methods, making it a popular choice for many businesses involved in bitumen.

1. Cost-Effective Solution

One of the primary benefits of Jumbo bag packaging is its cost-effectiveness. Compared to traditional packaging methods such as drums or cans, Jumbo bags are less expensive to produce and transport. Their large capacity allows more bitumen to be packed into fewer containers, which reduces shipping and storage costs.

- Lower cost per unit

- Reduced shipping costs

- Efficient storage and handling

2. Space Efficiency

Jumbo bags are space-efficient and can store large quantities of bitumen in a compact form. The bags are lightweight and flexible, allowing them to be stacked efficiently in storage or during transportation. This is particularly beneficial in warehouses or trucks, where maximizing space is essential for reducing overall costs.

- Optimized space usage

- Easy stacking and storage

- Flexible transportation options

3. Durability and Strength

The material used for Jumbo bag packaging, such as woven polypropylene, is known for its strength and durability. These bags are designed to withstand the weight of heavy bitumen without tearing or puncturing. This makes Jumbo bags a safe choice for storing and transporting bitumen, reducing the risk of spills or damage to the product during handling.

- Strong, tear-resistant material

- Protection against external factors

- Safe storage and transport

4. Environmental Considerations

While traditional packaging methods such as steel drums and plastic cans can be environmentally challenging due to their recyclability issues, Jumbo bags are more eco-friendly. These bags are reusable and recyclable, contributing to sustainability goals in the bitumen industry. Additionally, the large capacity of Jumbo bags reduces the need for excessive packaging materials, which is an advantage in terms of waste reduction.

- Recyclable material

- Reduced packaging waste

- Supports sustainability initiatives

Comparison with Other Bitumen Packaging Methods

While Jumbo bags are widely recognized for their efficiency in bitumen packaging, several other packaging methods are commonly used in the industry, such as steel drums, bitutainers, and bulk containers. Let’s explore how Jumbo bags compare with these alternatives in terms of key factors like cost, efficiency, and functionality.

1. Jumbo Bag vs. Steel Drums

Jumbo bag packaging in bitumen has notable advantages when compared to traditional steel drums, particularly in cost and space efficiency.

- Cost: Steel drums are generally more expensive to manufacture and purchase than Jumbo bags. Additionally, their design requires more space, both for storage and transport, leading to increased transportation costs.

- Space Efficiency: Steel drums take up more space than Jumbo bags, making them less space-efficient in storage and transport. This can result in higher storage costs and more complicated logistics management.

- Weight and Handling: Steel drums are bulkier and heavier than Jumbo bags, which increases handling complexity and labor costs. On the other hand, Jumbo bags are lightweight and easy to move, reducing labor requirements and transportation expenses.

2. Jumbo Bag vs. Bitutainer Packaging

Bitutainers are purpose-built containers for transporting bitumen, but when compared to Jumbo bags, they have both strengths and weaknesses. Here’s how Jumbo bags compare to Bitutainers:

- Cost Efficiency: Bitutainers are often more expensive than Jumbo bags, both in terms of production and transportation. They are specialized containers, which means they come at a higher cost compared to the versatile and reusable nature of Jumbo bags.

- Flexibility and Ease of Handling: Bitutainers are rigid and require specific equipment, such as cranes or trucks designed for their size and structure, for handling and transportation. In contrast, Jumbo bags are more flexible, and their handling can be done with standard forklifts or even manually, which is more practical for various scales of operation.

- Capacity: Bitutainers are designed to hold larger volumes of bitumen, typically up to 20-24 tons, making them a good choice for very large shipments. However, for smaller shipments or where flexibility is needed, Jumbo bags, with capacities ranging from 500 kg to 2,000 kg, can be more practical. Additionally, with the large volumes that Bitutainers hold, there may be fewer options for partial deliveries or smaller shipments, which could be a limiting factor.

- Storage Efficiency: While Bitutainers excel in capacity, their rigid structure can create challenges in terms of stacking and storing them efficiently. Jumbo bags, with their flexible and lightweight nature, are easier to stack and store in tight spaces, maximizing storage efficiency.

3. Jumbo Bag vs. Bulk Containers

Bulk containers are another option for transporting large volumes of bitumen. While they offer similar capacity to Jumbo bags, the flexibility and efficiency of Jumbo bags make them a better choice for many businesses.

- Flexibility: Jumbo bags offer more flexibility in handling. They can be moved with forklifts or even by hand if needed, providing an adaptable solution for different environments and operational needs. Bulk containers, however, typically require specialized equipment like cranes or trucks for loading and unloading, which can be less versatile.

- Cost-Effectiveness: Bulk containers can be more expensive to produce and transport, especially for smaller shipments. Jumbo bags, on the other hand, are a more cost-effective solution for both large and small volumes, making them suitable for a broader range of logistical operations.

- Space Efficiency: The rigid structure of bulk containers can make storage more complicated and less efficient than Jumbo bags. Since Jumbo bags are flexible and can be stacked more easily, they offer greater space efficiency, both in storage facilities and during transportation.

Jumbo Bag Packaging: A Reliable Solution for the Bitumen Industry

In conclusion, Jumbo bag packaging in bitumen offers several key advantages that make it a popular choice for manufacturers, suppliers, and distributors in the industry. Its cost-effectiveness, space efficiency, and durability make it an ideal packaging solution for large volumes of bitumen. When compared with other packaging methods such as steel drums, plastic barrels, and bulk containers, Jumbo bags prove to be a more efficient and environmentally friendly choice.

Key Advantages of Jumbo Bag Packaging:

- Cost-effective and space-efficient

- Durable and tear-resistant

- Eco-friendly and recyclable

- Flexible handling and transport options

For more information on packaging standards and the best practices in the bitumen industry, you can refer to the technical articles and guidelines published by ASTM International or ISO, which provide in-depth details on bitumen testing and packaging protocols.

By adopting Jumbo bag packaging, companies in the bitumen industry can enhance their logistics efficiency, improve safety during transport, and reduce costs associated with packaging and storage. This makes it a smart choice for businesses looking to streamline their operations while maintaining the high standards of quality and safety required in the

home / blog / factors affecting price of jumbo bags: Tips for economical shopping

factors affecting price of jumbo bags: Tips for economical shopping

jumbo bag price

Search in article content

Jumbo bags are large bags used to transport various materials, especially in the bitumen and construction industries. With their high capacities and durable structure, these bags are known as one of the most essential tools in various industries. When thinking about buying a jumbo bag, you should consider things such as its material, weight capacity, and application. The right choice can have a great impact on reducing costs and increasing productivity in the transportation process.

Why should you buy a jumbo bag?

One of the most important reasons for buying a jumbo bag is cost savings, and these bags can easily carry heavy materials due to their durable and flexible structure. In addition, jumbo bags reduce the number of times they need to be moved due to their size and high capacity, which reduces operating costs.

Other advantages of jumbo bags include ease of loading and unloading, reusability, and high durability. These features make these bags a more suitable and economical option for transporting materials compared to other packaging methods.

jumbo bitumen

Big Bag Price and Factors Affecting It

Factors such as material, size, brand, and purchase quantity have a great impact on the price of these products. The price of big bags may vary from 1$ to 3$. These price changes are especially noticeable in bags designed to carry sensitive materials such as functional bitumen. In addition, the price of 85/100 bitumen can also affect the price of these bags, because the bags must have high resistance to carry heavy and hot materials such as bitumen.

Factors affecting the price of a big bag

The following factors play an important role in determining the price of a big bag:

Material type and quality: Big bags made of heavy polypropylene or polyethylene usually have a higher price due to their higher resistance to chemicals and heavy weights.

Capacity and size: Big bags with higher capacity and larger dimensions usually have a higher price.

Special features: Features such as waterproofing, temperature resistance, and UV resistance can increase the price of big bags.

Supply and demand: When the demand for jumbo bags increases in the market, their price may increase.

Price of a one-ton jumbo bag

The price of a one-ton jumbo bag varies depending on its various characteristics, such as material, brand, and market conditions. For purchasing a one-ton jumbo bag, factors such as the price of raw materials, production cost, and market demand can have a great impact on the price. For example, in the Iranian market, the price of a one-ton jumbo bag typically ranges between 100,000 and 3$, but these prices may change depending on the specifications of the jumbo bag and the amount purchased. Jumbo bags that are made of more durable and stronger materials are usually more expensive.

Factors Affecting the Price of a One-ton Jumbo Bag

There are various factors involved in determining the price of a one-ton jumbo bag, as follows:

Bag Type: Jumbo bags that are made of more durable materials such as high-density polyethylene (HDPE) or polypropylene (PP) usually have a higher price.

Weight Capacity: Jumbo bags that have a higher load capacity and are able to carry heavier weights will naturally have a higher price.

Special Features: Features such as moisture resistance, waterproofing, or having stronger handles can affect the price of a jumbo bag.

Quantity: Bulk purchases from a vendor may reduce the unit price of a jumbo bag. Therefore, ordering in larger quantities can reduce costs.

Jumbo Bag Price

In the market, the price of a jumbo bag depends on the order volume, type of use, and additional features. In general, the price of a jumbo bag for industrial use starts about 2 dollars and can reach higher figures. In particular, the price of a jumbo bag in industries that need to transport special materials such as bitumen products, chemicals, and other industrial products may be higher due to the need for higher quality and resistance.

For example, jumbo bags for transporting bitumen or chemicals require features such as high resistance to chemicals and high temperatures, which can directly affect the price.

Important points when buying jumbo bags

When buying jumbo bags, in addition to features such as material and capacity, you should also pay attention to the following points:

Temperature resistance: It is essential to choose temperature-resistant bags for transporting viscous bitumen.

Waterproofness: In some industries, such as transporting bitumen, it is necessary for the bags to be waterproof to prevent moisture from penetrating the materials inside the bag.

Quality assurance and standards: Ensuring compliance with industry standards in the production of bags, especially for transporting bitumen and chemicals, is very important.

Ease of loading and unloading: The design of the bags should be such that the transportation and unloading of materials can be done easily and with minimal effort.

One-ton jumbo bag and its features

One-ton jumbo bags are specifically designed for transporting heavy materials. These bags are used to transport a variety of bulk materials such as bitumen, sand, gravel, and even chemicals. Especially the jumbo bitumen, these types of bags are used in many projects due to their high weight capacity and resistance.

When choosing a one-ton jumbo bag, you should pay attention to features such as resistance to pressure, temperature, and specific environmental conditions. These bags are usually made of high-quality materials and tear resistance, which makes them

Jumbo bag

Info

Spec

Jumbo Bag is a multi-layer bag that can prevent bitumen leakage.Moreover , they re high quality and resistance .in comparison to the new steel drum ,jumbo bags are more economical and they also reduce bitumen waste by 3 to 4 pecent.Jumbo bags are environmentally friend ly ,so they are highly recommande

Bitutainer Packaging is Not Applicable at This Time and Bulk Bitumen with Tanker Trucks Now is Applicable for Very Limited Destinations

Bitutainer or Bitumen Tank :

Suitable for storage and transportation of road construction bitumen.

Unique bitumen transport philosophy and 30% increase of loading capacity.

Max capacity of tank 25~45 (m3),Max weight of tank 4000~7800(kg),Dimensions of tank 6058*2438*2591(mm),12192*2438*2591(mm)Application pressure of tank 0.1(Mpa),Application temperature of tank 250() Furnished at the top with nitrogen valve to prevent asphalt aging As standard transportation of 20ft and 40ft ISO tank container Installed with high-quality heat-insulated device and solid shell Selectable hot oil heater pipe can centralize the system to use oil furnace for indirect heating, or use flues in the combustor or burners for direct heating Pump system selectable An ideal choice for seaway, highway and railway transport .

PolyBags & JamboBags

PolyBag & JamboBag Packaging is Not Applicable at This Season

Bitumen Polybags have a great advantage over those of old traditional Iron Drums. By use these bags the the wastage of bituman and that iron drum is prevented.

Comparing with traditional bitumen bucket, it has many advantages:

1. The bag is designed to melt along with the bitumen to form a homogeneous mass at a temperature between 160 and 170 Centigrade, without leaving any unmelted or partially materials.

2. The temperature of the molten bitumen pouring into the bag is 120~140 Centigrade.

3. The bag produces no pollution, and there is no package waste at the end-use.

4. No residual bitumen waste during the end-use.

5. To be Easy for shipping and storing.

6. Much more cheaper than steel drum packing.

Description:

Fusible bitumen bag is made of specific and unique poly-alkene compound. Comparing with steel drum and kraft paper package, it’s not only durable but also can be melted with the bitumen.

Overall features & benefits:

Melt Activator

As the end use with the bitumen at melted temperature 160º C~170º C, the Fusible Bitumen bag is not the polluted element but a good melt activator.

Save the Cooling time

No need to wait for hours even one night, no need to be stored on numbers of shelves, only need 1 hour’s refrigeration in water.

Abide High Temperature

The Fusible Bitumen bag is found to be capable of withstanding temperature at 130º C± 10º C in the bitumen-filling process. So the high temperature cannot affect the bitumen’s transportation and storage.

Economical

1)Innocuous and harmless bag, environment protection.

2)No any waste of bitumen with the Fusible Bitumen bag, instead of problems on how to remove remained bitumen from steel drum and how to deal with the broken kraft paper.

3)Saving more time and costs on bitumen packing, transport as well as other labor force.

Application:

The filling temperature should be ≤140 º C for the road bitumen.

The working house temperature for use should be ≥ 8 º C.

Both the poly and woven bags could be melted completely at 160º C–170º C, while the machine stirred about 20_30 minutes,

If in 20minutes, it means the inner bag could be melted completely at 160º C–165º C only.

In summer, this bag could be piled up at most for 5_6 layers. In winter, it could be piled up for 6_7 layers. Avoid piling too much to affect the quality of bag.

The elongation at break is ≥250%.

Reconditioned & Used Steel Drums

Reconditioned & Used Steel Drums Packaging is Not Applicable at This Time

At Isfahan Bitumen Drumming Factory we can take used steel drum containers and recondition them. This extends the life-cycle of the steel drum so that it can be reused. Drum reconditioning should not be confused with drum recycling.

Drum Reconditioning is the process of repurposing the drum for further use, where as drum recycling is taking a drum that has reached the end of its life cycle and crushing it to be melted down so that the steel can be reused..

PolyBags & JamboBags

PolyBag & JamboBag Packaging is Not Applicable at This Season

Bitumen Polybags have a great advantage over those of old traditional Iron Drums. By use these bags the the wastage of bituman and that iron drum is prevented.

Comparing with traditional bitumen bucket, it has many advantages:

1. The bag is designed to melt along with the bitumen to form a homogeneous mass at a temperature between 160 and 170 Centigrade, without leaving any unmelted or partially materials.

2. The temperature of the molten bitumen pouring into the bag is 120~140 Centigrade.

3. The bag produces no pollution, and there is no package waste at the end-use.

4. No residual bitumen waste during the end-use.

5. To be Easy for shipping and storing.

6. Much more cheaper than steel drum packing.

Description:

Fusible bitumen bag is made of specific and unique poly-alkene compound. Comparing with steel drum and kraft paper package, it’s not only durable but also can be melted with the bitumen.

Overall features & benefits:

Melt Activator

As the end use with the bitumen at melted temperature 160º C~170º C, the Fusible Bitumen bag is not the polluted element but a good melt activator.

Save the Cooling time

No need to wait for hours even one night, no need to be stored on numbers of shelves, only need 1 hour’s refrigeration in water.

Abide High Temperature

The Fusible Bitumen bag is found to be capable of withstanding temperature at 130º C± 10º C in the bitumen-filling process. So the high temperature cannot affect the bitumen’s transportation and storage.

Economical

1)Innocuous and harmless bag, environment protection.

2)No any waste of bitumen with the Fusible Bitumen bag, instead of problems on how to remove remained bitumen from steel drum and how to deal with the broken kraft paper.

3)Saving more time and costs on bitumen packing, transport as well as other labor force.

Application:

The filling temperature should be ≤140 º C for the road bitumen.

The working house temperature for use should be ≥ 8 º C.

Both the poly and woven bags could be melted completely at 160º C–170º C, while the machine stirred about 20_30 minutes,

If in 20minutes, it means the inner bag could be melted completely at 160º C–165º C only.

In summer, this bag could be piled up at most for 5_6 layers. In winter, it could be piled up for 6_7 layers. Avoid piling too much to affect the quality of bag.

The elongation at break is ≥250%.

Reconditioned & Used Steel Drums

Reconditioned & Used Steel Drums Packaging is Not Applicable at This Time

At Isfahan Bitumen Drumming Factory we can take used steel drum containers and recondition them. This extends the life-cycle of the steel drum so that it can be reused. Drum reconditioning should not be confused with drum recycling.

Drum Reconditioning is the process of repurposing the drum for further use, where as drum recycling is taking a drum that has reached the end of its life cycle and crushing it to be melted down so that the steel can be reused

Agriculture: Larger bags for lightweight goods like grains or animal feed.

Construction: Smaller, heavy-duty bags for gravel, bricks, or concrete.

Recycling: Flexible and spacious bags to store bulk scrap materials or plastic waste.

Storage and Transport Constraints

Storage space and transportation methods also play a role. Compact bags with baffle inserts can optimize space utilization in warehouses or shipping containers. Additionally, bags designed with integrated lifting loops or forklift-compatible sleeves simplify material handling.

Environmental Conditions

Environmental factors, such as exposure to moisture or UV light, may necessitate specific bag types or coatings. For example, UV-treated jumbo bags are suitable for outdoor storage, while moisture-resistant liners are essential for materials prone to water damage.

How Size Affects Weight and Pallet Configurations

The size of a jumbo bag has a direct impact on its weight distribution and how it fits on standard pallets or within transport vehicles. Proper planning in this regard can improve operational efficiency and reduce logistical costs.

Weight Distribution

Larger bags allow for greater capacity but require careful attention to weight limits. Overloading can compromise safety and increase the risk of bag breakage during handling. Smaller bags, while lighter, may lead to higher transportation costs due to the need for additional units.

Pallet Utilization

Jumbo bags are often used in combination with pallets to simplify loading and unloading. Standard pallets (typically 48x40 inches) can accommodate:

Small Jumbo Bags: 2-4 bags per pallet.

Medium Jumbo Bags: 1-2 bags per pallet.

Large Jumbo Bags: Usually 1 bag per pallet.

Efficient pallet stacking can maximize truck or container capacity, reducing overall shipping expenses.

Stacking and Stability

The height and shape of jumbo bags affect their stackability. Bags with baffles maintain a uniform shape, allowing for safe stacking. Irregularly shaped bags or overfilled units may compromise stability, leading to potential safety hazards during storage or transit.

Conclusion

Jumbo bags are indispensable for a wide range of industries due to their versatility, durability, and cost-effectiveness. Understanding the various sizes available, the factors influencing their dimensions, and the impact of size on weight and pallet configurations can help businesses make informed decisions. Whether you're transporting lightweight grains or dense construction materials, selecting the right jumbo bag size is key to optimizing efficiency and ensuring safety.

FAQs

What are the standard sizes of jumbo bags?

Jumbo bags typically range from 35x35x35 inches to 42x42x72 inches. Smaller bags hold around 500-1,000 kg, while larger bags can handle up to 2,000 kg, depending on their design and safe working load (SWL). Custom sizes are also available for specialized applications.

How do I determine the right jumbo bag size for my needs?

Consider the material’s density, weight, and volume. For lightweight or low-density items, opt for larger bags to maximize capacity. For heavy or high-density materials like gravel, smaller, reinforced bags are safer and more practical.

What factors influence the choice of jumbo bag size?

Factors include the type of material (e.g., sand, grains, or scrap), SWL ratings, storage space, and transport constraints. Environmental conditions, such as UV exposure or moisture, may also require specific bag coatings or liners.

How does bag size affect pallet stacking and transportation?

Smaller bags (up to 1,000 kg) fit 2-4 per standard pallet, while larger bags (over 1,500 kg) typically fit one per pallet. Baffle bags help maintain shape, allowing for safer stacking and efficient use of storage or shipping space.

Are jumbo bags reusable, and does size affect reusability?

Yes, many jumbo bags are reusable, especially those designed for multiple cycles with proper care. Larger or heavier-duty bags are more likely to withstand repeated use, but their reusability depends on material quality and adherence to safe handling guidelines..